Our R&D team is a strategic asset for the company, responsible for technological leadership. We focus on two key areas: continuous optimization of existing products and the creation of innovative solutions that set new industry standards.

To achieve these goals, we have a robust research complex, comprising several specialized laboratories. This allows us to cover the full development cycle, from fundamental research to pilot testing.

We operate seamlessly with our manufacturing and sales teams. This approach ensures that our projects have clear practical applications and solve real-world problems our customers face.

This is the central link in our R&D chain. In our synthesis laboratory, we create unique chemical compositions that form the basis of product solutions for our customers. Our developers provide a full development cycle, ensuring that the product perfectly meets the most complex technical requirements.

Key advantages:

- Deep expertise in creating complex formulations: Our technologists understand the synergy of components and can purposefully influence the properties of the final product.

- Modern equipment for precise synthesis and analysis. Each stage is controlled, and the result is monitored and evaluated.

- Focus on key product properties: We are interested not only in the composition, but also in its performance characteristics: adhesion, heat resistance, tribological characteristics, environmental friendliness, stability.

- End-to-end development process: From fundamental research to pilot batch creation and transfer to testing.

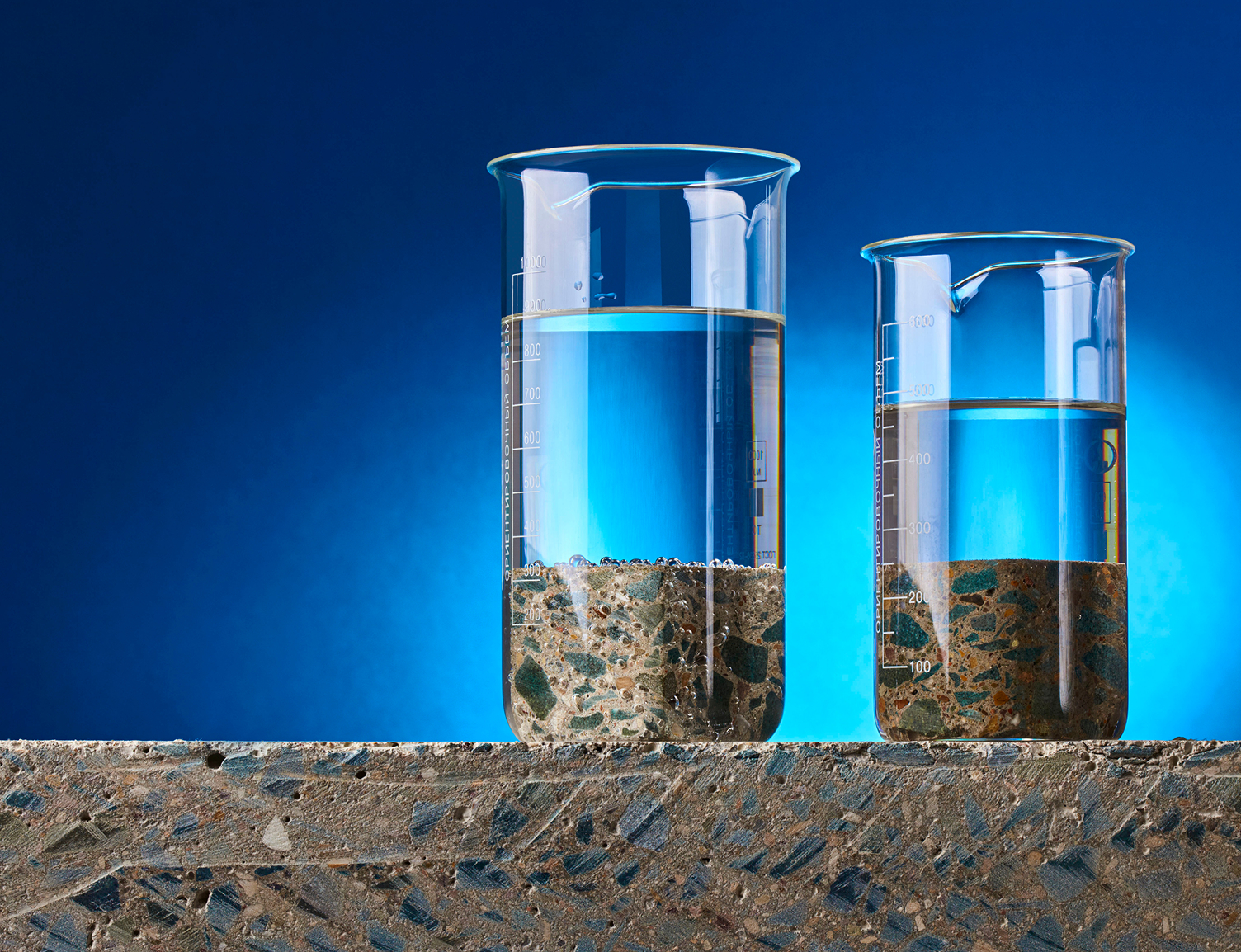

Here we provide evidence of effectiveness and durability. By simulating extreme conditions and loads, we test and confirm the performance characteristics of all products. Our task is to simulate many years of operation in a short period of time to ensure the smooth operation of our solutions in aggressive environments at critical temperatures.

Key areas:

- Tribological research: tests for friction, wear and anti-seize properties of lubricants and coatings.

- Accelerated corrosion tests (salt spray, cyclic climatic effects).

- Mechanical and adhesion tests: adhesion strength, impact resistance, chipping, tensile strength.

- Thermal tests: performance at high and low temperatures, thermal stability, fire resistance.

- Chemical resistance: exposure to acids, alkalis, solvents, technical fluids.

- Bench and field tests: simulation of real operating conditions on equipment.

We don't just test — we predict service life and confirm the superiority of our solutions.

RECIPES

We create chemical products that perfectly match your processes and operating conditions. Our development begins with a thorough analysis of industry challenges and production requirements.

We tailor formulations specifically for you based on key parameters:

- precise viscosity and flowability indicators

- specified heat resistance level

- targeted anti-corrosion properties

- special adhesive characteristics

- anti-seize and anti-wear properties

- stability in aggressive environments

As a result, you receive not just a chemical composition, but a complete technological solution that improves equipment efficiency, reduces operating costs, and increases the profitability of your business.

TEAM

We actively cooperate with relevant universities and research institutes, participating in joint projects and specialist training programmes. This allows us to be at the forefront of technological innovation and offer the market products that meet the most modern requirements.

Such multifaceted interaction provides a synergistic effect, transforming scientific developments into effective commercial products for various industries.